[Product] 3-layers membrane presentation

Posted on 2020-07-07 16:28:15 in news

To date, the term “single-wall” worries a majority of passionated, experts and amateurs. The tent, this thousand-years-old object was the first habitat built by the human being. Evolving little by little over the years, The North Face® revolutionized its design by developing the first flexible poles. The first dome tent was launched in 1966. By removing the central pole, the interior comfort was considerably optimized.

The evolution of the textile industry made it possible to switch from cotton to RipStop nylon in the 1980s. Double-walled tents made their appearance. A first wall to ensure waterproofing and a second wall to form a living space.

Waterproof breathable single-wall tents were then developed, but never achieved the optimal performance to guarantee an acceptable compromise between breathability and waterproofness. Not very popular, they were used by practitioners willing to sacrifice one or the other for the benefit of weight.

Following an ambitious R&D process, Samaya® offers the first non-condensing single-wall 4-season tent. Innovative materials and a ventilation system make it possible to unite waterproofness, breathability and lightness.

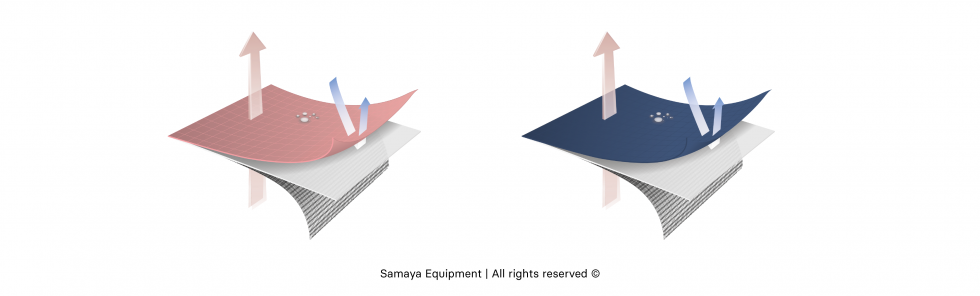

Samaya® finds its supplier in Japan, one of the three countries (Japan, Korea and Taiwan) that are world leaders in technical textiles. Ghislain Pipers and Arthur Jallas, the two co-founders, went in person to meet him to ensure the quality of the fabric. This three-layer laminate is composed of a 7D RipStop Nylon fabric, a PU Membrane 7μm and a 7D Hydrophilic Nylon knitwear. Optimized, the fabric has the best weight-to-strength ratio found on a woven fabric. Woven in MicroRipStop 7D Nylon, it ensures the mechanical resistance of the fabric. RipStop consists of inserting a thicker thread at regular intervals to prevent the propagation of a tear. The central component of this fabric is a monolithic PU membrane from 7μm. The thicker this membrane is, the more waterproof and heavy it is, the thinner it is, the more breathable and lighter it is. Without leaving anything to chance, Ghislain Pipers has developed the membrane that perfectly combines impermeability (ISO 811 test), breathability (ASTM 96) and lightness. A monolithic membrane does not have micropores, it is a solid surface which by chemical process will transfer moisture to the outside. A temperature/humidity gradient between the inside and outside of the tent will influence the transfer. The backing (the third layer on the inside of the tent) is a 100% 7D hydrophilic Nylon knit. This will absorb moisture from the environment and keep it close to the membrane to facilitate the transfer to the outside.More or less soaked, the knit fabric limits the formation of droplets to a minimum.

In summary, the walls of the Samaya2.5 are made of a 3-layers laminated fabric. The waterproofness is 20,000 Schmerber and the breathability is 40,000 g/m²/24h, the weight is 54g/m². The symbiosis of its three layers allows to combine lightness, high performance and technical durability.

Need some advice?

Need some advice?  Free Delivery

Free Delivery  Secure checkout

Secure checkout  Find a dealer

Find a dealer